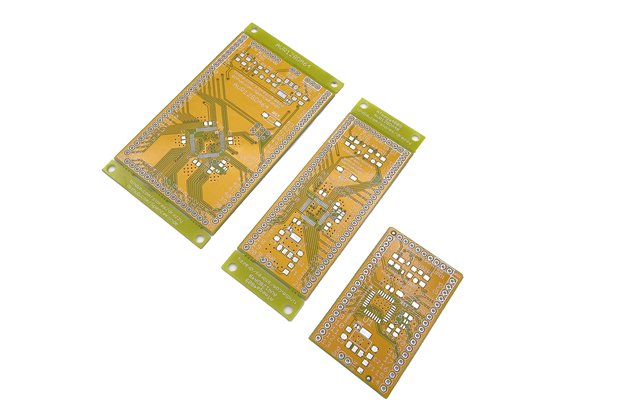

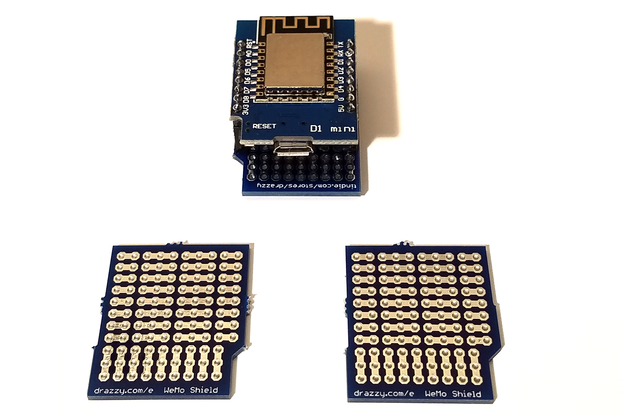

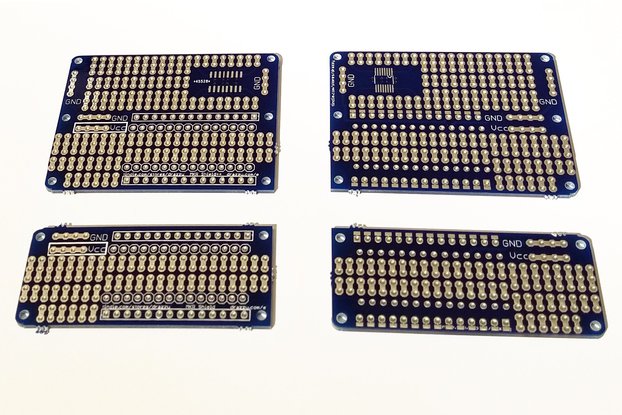

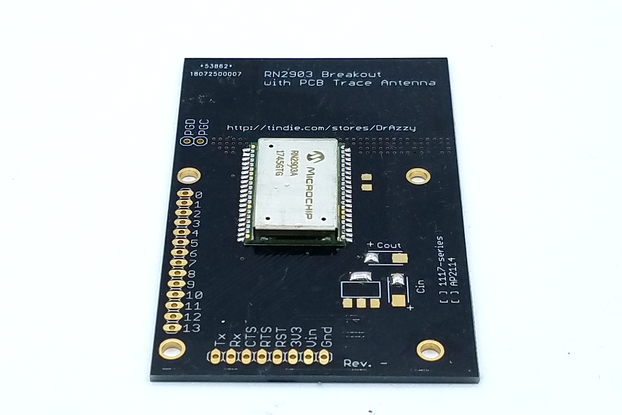

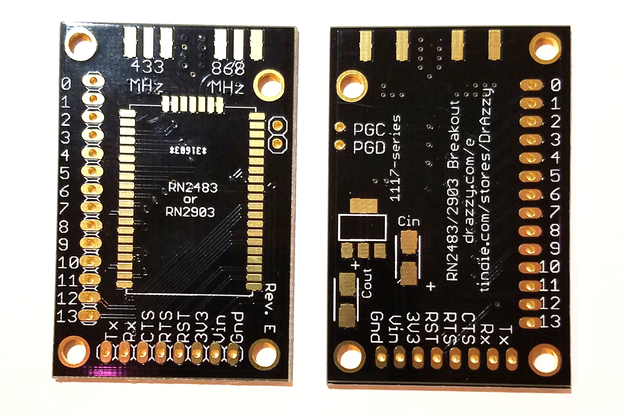

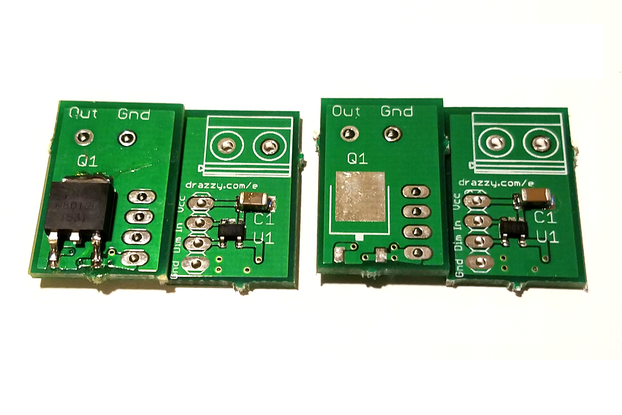

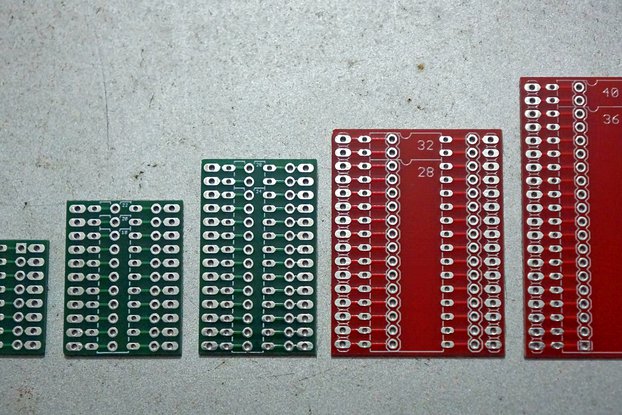

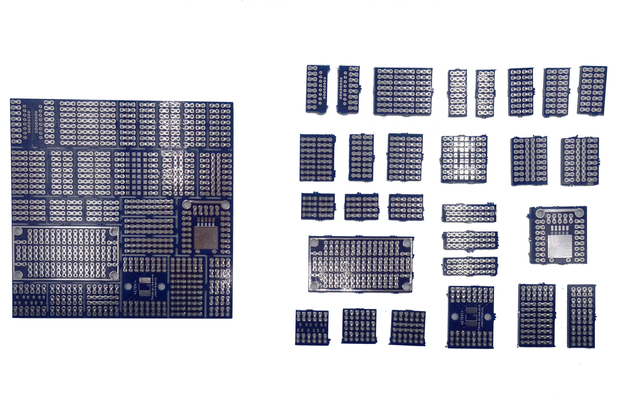

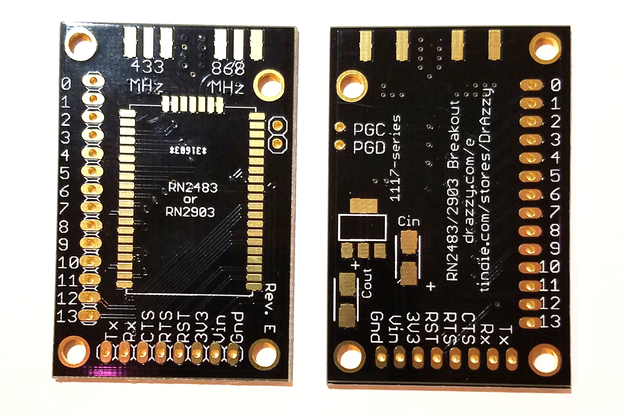

Superior breakouts for DFN, QFN and similar in 6 8, 10, 12, 16,20, 24, 28, and 32-pin packages

Designed by Azduino by Spence Konde in United States of AmericaThis seller is taking a break. Sign up below to get an email when they're back!

No shipping info available.

Set destination country to see options

Shipping to starts at

Free shipping is available to !

Ships from

This item does not ship to .

More Info

Sign up and we'll send a reminder when the seller returns!

Better, cheaper breakout boards! Breakout boards for the most common SMT footprints are everywhere. SOIC and TSSOP? Everyone and their dog has those for sale. We're not going to try to compete with t…

Read More…Breakout boards for the most common SMT footprints are everywhere. SOIC and TSSOP? Everyone and their dog has those for sale. We're not going to try to compete with those. Unfortunately, these days the most exciting parts don't always come in those convenient easily soldeed packages that we all love. They come in "no-lead" packages. To make matters worse, while the name still identifies the overall shape most of the time (though many manufacturers have in-house names to refer to largely standard packages), and the number of pins, for sizes smaller than TSSOP, the package name is no longer specific to identify the actual footprint! There are, for example, at least 4 different packages called QFN12, QFN20, and QFN28! It's a common misconception that the added first letter relates in any way to the package footprint. A QFN20, VQFN20, WQFN20 and UQFN20 may all exist, but the initial letters like T, V, W, and U have nothing to do with the footprint. Those stand for Thin, Very Thin, Very Very Thin (VV looks like W, and so that's what's often used), and Ultra Thin)...

However, an M (as in MSOP) does say something - though less than you might like: an MSOP is a "Micro Small Outline Package", smaller than an SSOP (Shrink Small Outline Package) which is in turn smaller than an SOP ("Small Outline Package") - though MSOP does not identify the package uniquely; you know an MSOP-16 will be smaller than a TSSOP-16, and that it has leads, unlike a DFN-16. But will the pin pitch be 0.65mm? Or 0.5mm? You'll have to refer to the package drawings in the datasheet to figure that out...

The picture as relates to DFN (Dual Flat No-lead) is similarly murky. There are DFN's available with many pin pitches, though only three different pitches are commonly seen in the wild - 0.65, 0.5, and 0.4mm. Each of those might be found with or without an exposed pad between them, and where present, the exposed pad width (and hence the width of the whole package) varies between devices.

It is, to use a technical term, a total shitshow, and an inexperienced buyer can easily end up with a breakout board (or worse, a custom made PCB) with a footprint that doesn't match their part. Sometimes the same part is even made in multiple packages with the same basic "name" (ex, VQFN-20), but different pin pitches. I ran into this the hard way, when I failed to notice that the ATtiny841 was made in two different VQFN-20 packages: One with 0.5mm pin pitch, and another with 0.4mm pitch. My boards came in, and the chips arrived, and I eagerly started trying to assemble one... and then realized that I'd used the 0.5mm, 4mm x 4mm footprint... but ordered 100 pcs of the smaller version. Ooops. (That's what happened to Rev. D of the tiny841 breakout....)

As mentioned above, the waters are further muddied by vendor-specific names: Some companies like to call DFN parts things like SON/TSON ("[Thin] Small Outline No-lead"), or refer to some of their QFN packages as MLF. "MLF?, huh?" That's the "Micro Lead-Frame", which describes the internal construction most QFN parts. I'm sure if one happened to know the inside development story for those vis-a-vis various technologies, a company's naming patterns would make some level of sense - but for everyone on the outside, this is just more muddying of the water. Nobody cares about the precise details of the manufacture of their chip as long as the chip works. Do I care that this chip is made using a micro lead frame? (no!) From the outside, though, it looks pretty random.

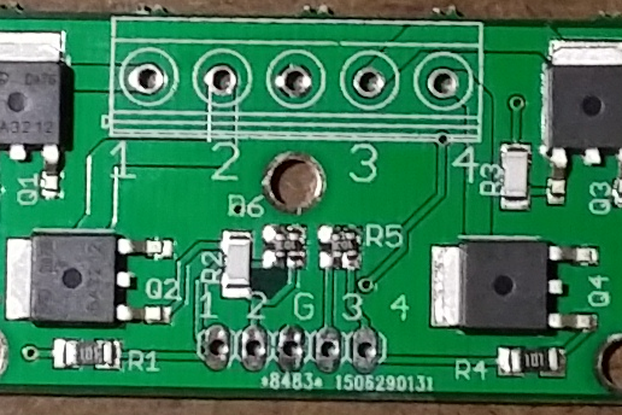

Unsurprisingly, there are specialist suppliers who manufacture breakout boards for a great variety of these wacky parts. I have been profoundly disappointed with their product. The best known of these is a certain manufacturer who I won't mention by name, with what seems to be an incredible selection of breakout boards. At the exorbitant prices they charge (sometimes as much as $10 per breakout board), you'd think you would be getting carefully designed boards, with attention paid to the details that make the difference between an easy to use board, and something that, well, maybe you could solder it with a good hot air reflow station and a microscope.

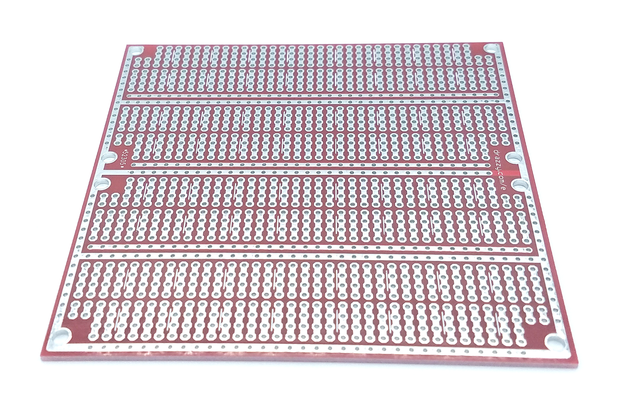

You'd be wrong - what they (and the other major manufacturer of obscure breakout boards) sell is actually pretty lousy. Exposed pad? If they bothered to include it, it's solderable by hot air or reflow oven only: there's no provision for getting heat to it otherwise, and if the manufacturer specifies that the exposed pad has to connect to something, you're out of luck: even when present, they didn't have the courtesy to connect it to any sort of termination: It's just an island of exposed copper in the middle of the footprint. The footprint itself? Well, that's going to be the canonical one given in datasheets (usually without the EP, as noted). This footprint is designed to be used with parts placed precisely by machine, and soldered in a reflow oven. You're not going to be using a pick and place machine to place the parts for your prototype onto a breakout board, and there's a good chance you won't be using a reflow oven either...

That ground plane that the manufacturers of parts often describe as a necessity? Keep dreaming. The manufacturing quality of the boards? Far from inspiring. Really nothing about them stands out - they're mediocre boards with pads prone to lifting off the PCB (more so than my boards, at least) - At least they (mostly) have bothered to use ENIG surface treatment. It's my opinion that these breakout board manufacturers are taking advantage of their customers, who have few options - either buy their breakout board, buy a likely overpriced eval board, or hire a PCB designer to make a custom board to mount the part on. Until now...

We've reimagined the essential features of a breakout board to address the common challenges of working with parts in wacky, fine-pitch, no lead packages, to facilitate rapid assembly and minimize the misery that comes with no-lead parts.

Note that if the exposed pad is about the same size, and the pin pitch is the same, you can use a smaller DFN than the board was designed for - that is, a 0.5mm pitch DFN6 could be mounted on the DFN16A (in fact, two of them could even be mounted on the same board, unless they are very odd shaped DFN6's.

The following shorthand is used: 0.5p, = 0.5mm pin pitch, 0.5EP = 0.5mm wide exposed pad.

The pads extend outward farther than would be needed to accommodate the width of any plausible part. The catch comes from the EP. If the EP on the chip is much wider, then the pads on the PCB for the pins will short to the exposed pad on the underside of the chip, and if the opposite is true, the the pins will reach the center pad of the PCB with the same effect. Luckily the widths do not vary continuously - there seem to be a few widths that get used by many manufacturers, to within 0.1mm of each other - for the most part. There are always a few companies that just have to do things differently.

Other names for these packages include WSON (Wide Small Outline No-lead - often for wider packages, though dimensions vary), TDFN (Thin DFN), and sometimes more exotic names like XSON-8 (often a gigantic 8-pin no-lead package used for large capacity flash chips - they definitely couldn't call this a DFN, as the pin density is quite low; non-leaded package is used for reasons other than a need to make the overall product smaller) and USON (not sure what the U stands for. "Unusual" would be accurate, but not great marketing. DFN breakouts are also suitable for MSOP (Micro Small Outline Package), VSSOP (Very-thin Shrink Small Outline Package), and SM8 packages. None of these packages uniquely specify one pin pitch - there are 0.5mm and 0.65mm MSOPs, for example, and the presence or absence of an exposed pad on the parts with leads depends on economic decisions and the design requirements of the manufacturer.

| Model | Availability | Side A Footprint | Side B footprint | Grounds | Surface Treatment | Row Spacing | sold in packs of | Hole |

|---|---|---|---|---|---|---|---|---|

| DFN6A | Now | SOT-23-6 | DFN6 0.65p No EP | Plane/Stripes | ENIG | 0.3" *** | 6/$5 | No |

| DFN6B | Now | SOT-23-6/0.4mm DFN | 0.65mm DFN6 | Plane | ENIG | 0.5" | 6/$5 | No |

| DFN8 | Now | DFN8 0.65p 1.5EP | DFN8 0.65p No EP | Plane/Stripes | ENIG | 0.5" | 12/$8 | No |

| UQFN8 | Now | UQFN8 1.4x1.7mm | XSON-8 5x6 mm | Plane/stripes | ENIG | 0.5" | 4/$5 | No |

| DFN10 | Now | DFN10 0.4p 0.5EP | DFN10 0.5p 1.2EP | Plane only | ENIG | 0.5" | 6/$5 | Yes |

| DFN16A | Now | DFN16 0.5p 0.9EP | DFN16 0.5p No EP | Plane side A | HASL | 0.75" ** | 4/$3 clearance | Two |

| DFN16B | Now | DFN16 .65p 1.6EP | DFN16 .65p No EP | Plane side A | HASL | 0.75" ** | 6/$5 clearance | Two |

| DFN16C | Now | DFN16 0.5p 0.9EP | QFN16 0.5p 3x3mm | Plane side A | HASL | 0.75" ** | 6/$4 clearance | Two |

| DFN16C (new) | Now | DFN16 .65p 1.6EP | DHVQFN16 * | Plane/Stripes | ENIG | 0.5" | 4/$5 | Two |

| DFN16D (new) | Now | mQFN16 .4p 3x4mm | 2xDFN8 0.4p No EP | Plane/Stripes | ENIG | 0.3" *** | 5/$5 | Small |

| DFN16B (new) | Soon | DFN16 .65p 1.6EP | DFN16 .65p No EP | Plane/Stripes | ENIG | 0.5" | 4/$5 | Two |

| DFN16A | Now | DFN16 0.5p 0.9EP | DFN16 0.5p No EP | Plane/Stripes | ENIG | 0.5" | 4/$5 | Two |

DFN6 has two footprints on side A, a SOT-23-6 and 0.04mm DFN-6 with no EP.

DFN8 Side B has a DFN8 0.65mm pitch with no EP. This also fits a SOT-23-8.

* DHVQFN16 is NXP's pet package. It is a strange hybrid of a QFN and a DFN, 2.5x3.5mm in size, and is not used by other manufacturers. Bizarely, the EP is most often tied to Vcc. To cater to this possibility, there are 8 bridges in the corners - cutting the 4 next to either set of pins will sever the connection between the ground plane and the stripe on that side, and the mounting hole is not tied to the ground plane.

** Due to a design mistake, the current stock of these boards has a row spacing not divisible by 0.1, and so does not connect cleanly to 0.1" spaced prototyping board.

*** this cannot be fit into a wide DIP socket... but it will fit a narrow DIP socket! Also, on SOTDFN6, there rows of holes have 6 pairs of holes on either side, and each footprint is by default connected to only one side. You can connect the two by bridging the solder bridge pads if desired, or if you happen to need both a DFN6 and a SOT23-6 part in the same project, you can use both sides and not bridge the pads (and really, what project doesn't need a SOT23 part for something?).

Bridging the pads may also be useful if making some sort of an inline adapter that would go in the middle of a cable with a buffer, or similar device being mounted on the board, where you might want to connect wires to both sides of the board (pro tip: connect the wires to the board on the edge opposite where they came in, and hold them in place against the back of the PCB with liberal application of ~hot-melt glue~ thermoplastic adhesive (never say you're going to "glue" something, always "utilize adhesives" - glueing something sounds unprofessional, but adhesives? You must know what you're doing!) But seriously, the glue-as-strain-relief method is used very heavily in industry for exactly this purpose - open up most old VCRs and things of that sort, even kids toys with lights on widely distant parts of the toy, and you'll see wire soldered to the PCBm and then stuck down with glue and/or looped through a slot in the PCB. This will prevent them from fatiguing and snapping during normal handling, which it is normally prone to, as many of you will know from experience (the solder wicks up into the wire which makes the wire rigid, but there is a sudden transition from flexible to non-flexible some distance up the wire and that is a natural stress point. Hot Glue is very good at preventing this, as it has a fair amount of give to it that it won't just create a new stress point, but will prevent any flexing from happening at the most vulnerable point).

Where there's more than one model for a given pincount, we try to maximize the sum of the difference between sizes of the parts on the two boards. So given pitches of 0.4, 0.45, 0.5 and 0.65, we'd pair the 0.65 and 0.45, and the 0.4 and 0.5. This minimizes the chance that one might try to use the wrong side and not notice until you'd made a mess of it. There's not much more maddening than using a reflow oven to solder a a 0.45mm pin pitch package onto a 0.5mm footprint. You'll think you're so close to being able to make it work, but even though it looks so close... no amount of heroic rework efforts short of removing the part and putting it on a proper footprint will be successful (speaking from bitter experience). By not putting the most easily-mistaken-for-eachother sizes on the same board, as long as you ordered the right board, you are guaranteed to not have two packages of near-identical size on opposite sides, begging you to get them mixed up.

| Model | Availability | Side A Footprint | Side B footprint | Grounds | Surface Treatment | Row Spacing | sold in packs of | Hole |

|---|---|---|---|---|---|---|---|---|

| UQFN8 | Now | UQFN8 1.4x1.7mm | XSON-8 5x6 mm | Plane/stripes | ENIG | 0.4" | 4/$5 | No |

| QFN10A | Now | QFN10 0.4p 2323 | QFN10 0.4 p 2323 | Plane/Stripes | ENIG | 0.4" | 6/$5 | Yes |

| QFN10B | Now | QFN10 0.4p 1414 | USON10 Special | Plane/Stripes | ENIG | 0.4" | 6/$5 | Yes |

| QFN12A | Now | QFN12 0.4p 2x2mm | QFN12 .65p 4x4mm | Plane/Stripes | ENIG | 0.4" | 6/$5 | Yes |

| QFN12B | Now | QFN12 0.8p 4x4mm | QFN12 0.5p 3x3mm | Plane/Stripes | ENIG | 0.4" | 6/$5 | Yes |

| QFN16 | Now | QFN16 .65p 4x4mm | QFN16 0.5p 3x3mm | Plane/Stripes | ENIG | 0.4" | 6/$5 | Yes |

| DFN16D | Now | mQFN16 .4p 2x3.2mm | 2xDFN8 0.4p No EP | Plane/Stripes | ENIG | 0.3" * | 5/$5 | Small |

| QFN20A | Now | QFN20 0.4p 3X3mm | QFN20 0.5p 4x4mm | Plane/Stripes | ENIG | 0.5" | 4/$4.50 | Yes |

| QFN20B | Now | QFN20 .65p 5x5mm | QFN20 .45p 3x3mm | Plane/Stripes | ENIG | 0.5" | 4/$4.50 | Yes |

| QFN24 | Now | QFN24 .65p 5x5mm | QFN24 0.5p 4x4mm | Plane/Stripes | ENIG | 0.5" | 4/$5.50 | Yes |

| QFN28A | Now | QFN28 .65p 6x6mm | QFN28 .45p 5x5mm | Plane only | HASL | 0.6" | 4/$6 | Two |

| QFN28B | Now | QFN28 0.5p 5x5mm | QFN28 0.4p 4x4mm | Plane only | HASL | 0.6" | 4/$6 | Two |

| QFN28C | Now | QFN28 0.5p 5x6mm | TSSOP28 w/EP | Plane only | HASL | 0.65" ** | 4/$4 Discounted | Two |

| QFN32A | Now | QFN32 .65p 6x6mm | QFN32 0.4p 5x5mm | Plane only | ENIG | 0.6" | 4/$7 | Two |

| QFN32B | Now | QFN32 0.5p 5x5mm | QFP32 0.8p 7x7mm | Plane only | ENIG | 0.6" | 4/$7 | Two |

| SOIC16C | Now | SOIC16 + caps | SSOP16 + caps | Plane/Stripes | ENIG | 0.5" | 6/$5 | Two |

* this cannot be fit into a wide DIP socket... but it will fit a narrow DIP socket!

** Due to a design mistake, the current stock of these boards has a row spacing not divisible by 0.1, and so does not connect cleanly to 0.1" spaced prototyping board.

QFN28C is has the rectangular package with 8 pins on two sides and 6 on the other two. Analog Devices likes it.

QFN32B has a QFN footprint on one side, and a QFP footprint on the other; that's the most common 32-pin flatpack package. Breakout boards for QFP-32 are hardly difficult to find, though most of them are worse than these. What makes these unique is that they provide an exposed pad. You don't often see something in QFP32 that requires an exposed pad, but when you do, they generally specify that you need to have it connected (otherwise they wouldn't have put it there, like all the other QFP parts).

QFN10A, QFN10B. (3 footprints for QFN10) plus a DFN-variant sold as USON-10. There are two shapes (2 pins on 2 sides and 3 on the others, and 1 pin on 2 sides and 4 on the others for a QFN10 and one of them is available in two different pin pitches. Both have been described as having slightly different physical dimensions depending on the manufacturer. The USON is yet another whackjob package that is shipping on production parts. It's like a DFN, 0.5mm pitch, with extra wide middle pin on each side. No, I cannot fathom why, either). Planned pricing $5/6

XSON/UQFN8 - XSON with exposed pad on one side, UQFN (3 pins on one 2 sides, 1 on the other 2 sides, 0.5mm pitch, 1.5x1.7mm). XSON8 is a much larger package - 0.8mm pin pitch - but it has an EP that you're supposed to solder down in the middle of it. I encountered it in the context of Winbond flash ICs, and it appears to be popular for such parts (particularly high capacities - it may be forced upon them by the die size. )

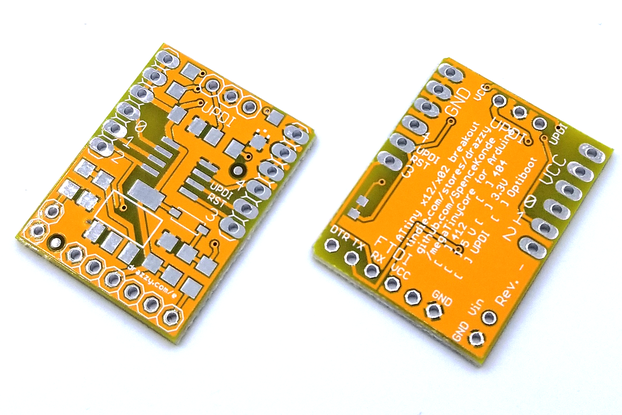

DFN6 - DFN6 with 0.4mm pitch one one side, and 0.65mm pitch on the other. Both are in common circulation. There was extra space on the board, so I put a SOT-23-6 footprint on as well. Since we sell them by the six-pack instead of the single board, you'll probably have some extras, and there's always something in some SOT23-6 or SOT-23-5 package that you need for something

DFN16D "miniQFN" 2mm x 3.2mm 0.4mm pitch. the shorter sides are completely filled by the pins, while on the longer pins, the pins start only once they clear the pins on the thinner ends. I happened to need some of these myself too; the only package in which this analog switch that was perfect for my needs wasn't backordered to absurdity in was this silly package. (several manufacturers use it with slight variation) with no EP, with two 0.4mm pitch DFN-8 packages on the back). It was quite possibly the most unpleasant package I've ever soldered!

SOIC16C - This has a TSSOP16 on the bottom, SOP/SOIC16 on the top. But it also has pads to solder 1206 decoupling caps real close to the chip. Obviously, not all parts have power and ground positioned on the same pins - but most either have it to the two corner pins (hint: you can rotate the part soas to use the right opposite-corner pins), or two pins one one end or the other. Those are the pins we had room to give a decoupling cap to.

There is definitely room for a more thorough treatment of the larger DFNs, but I'd like to get some feedback on these from customers and let that inform my decision of what to do next on this front.

I'm considering offering the service of mounting parts onto these PCBs, as I've gotten reasonably good at it soldering these successfully, and I know many people are not comfortable soldering these sort of packages. Message me if this is something you would be interested in

Have we missed any? Please give suggestions for underserved packages!

There is only one real constraint here:

We will pull the datasheet for the part. If it is obvious that the part has a footprint that is deeply specialized will not make breakout boards that won't be fit for purpose, or won't provide a level of safety that I'd be comfortable distributing. Usually these whackjob parts come from companies that seem to be suffering from a bad case of not-invented-here syndrome when they decide which packages to use, and create novel unique packages that are different from everyone else's (and then, these days, often fail to provide reliable supply of the parts at hand) - but sometimes there is a very concrete reason that the part has such a strange package. This (far and away) most frequently seen in small PMIC parts that nonetheless are designed to deal with mind-blowingly large currents for the size of the package. TI, which is well known for using wacky packages, seemingly just for kicks, sometimes actually has a very good reason for it. Their ""Hotrod QFN10" for example, a tiny QFN16 that looks like the sides got squished closer together so the 4 corner pins merged, and with two of the pads extending the whole width. A - it's that way because of the high current it carries. It needs a dedicated board designed specifically the application. This is one of the times you'd probably want to use the company's Eval board.

I was recently asked about an EFuse chip from TI. The package it had was probably the weirdest package I had ever seen, with the exposed pad divided in half and a line shaped like interlocking fingers between them. It didn't take much consideration to realize that a) the part, if aligned even slightly off of the perfect alignment, the pads would be shorted to each other under the chip. since those pads were the two sides that the e-fuse was supposed to disconnect under fault conditions, that would be a Bad Thing, because it would not be detectable in non-fault conditions, and b) even TI wouldn't make a package that weird for no reason (and they love weird packages). So I start paging through the datasheet trying to spot some reason for such a strange package. It doesn't take long to find it: That would be because of the maximum current rating... THIRTY-FIVE AMPS, through something a few millimeters on a side! But something handling such extreme currents presents obvious hazards, which is why you would put a fuse or circuit breaker or efuse IC into such a circuit. But that wouldn't be able to do it's job if it was soldered slightly cockeyed or skewed, since the two sides it's supposed to disconnect would be shorted by the solder; such soldering errors could be invisible without x-ray imaging (which is sometimes done for critical systems industrially, and is common in electronics assembly process development). Beyond the fact that the part in question is a protection device which needs to work consistently, which won't be likely with any sort of home soldering process or readily detectable either, at that kind of current, even normally straightforward things, like connecting the wires, are no longer trivial. This is the sort of part that needs to be designed into the board, and may not be practical to solder at home at all (it would require some empirical testing to see whether a shorted one behaved differently in some measurable way without putting >35A through it. I will not make breakout boards for packages only used for parts for which a generic breakout board is not going to be viable (there must be parts that will draw, at most, a few amps (more than that, and you need to design a custom board anyway to accommodate the connector(s) you plan to use to handle such large loads (2-3A is most you can get through a 1p DuPont connector to pin header - and the dupont (knockoff DuPont) pins we normally see in hobby electronics are considerably worse), or sufficiently sized wires - 35A for example would require 13 AWG wire to follow typical design guidance figures), and it must not be a package used only by parts that are unusually layout sensitive and which would be unlikely to work without severe performance degradation (such RF parts, switching DC/DC converters, and similar).

Outside of that, pretty much anything is fair game, as long as it there is at most one termination (the EP) that is hidden when the chip is installed. No BGAs, no dual row QFN, or other things like that - things that can't plausibly be assembled with high yield without a stencil and reflow oven. I'm particularly interested to know which of the many rectangular QFNs that can be described mathematically (for N=Pincount/4, and a given pitch, there are N-2 possible shapes of the package - the 2 that are subtracted from the total simply being the extremes of square QFN and a DFN) actually exist in production hardware (you often cant spot them on parametric searches, because generic images of a QFN are used most of the time, rather than photos, the shape of the package is not always listed, and even when it is, the accuracy of digikey/mouser/etc's parametric search information is a bit of a crap shoot), and of those, which are actually packages that people end up wanting breakout boards for? I suspect there are some packages that are not all that exotic statistically - but which are only found on parts that aren't going to see use by hobbyists for one reason or another ("Yes just ask your sales rep and they'll get a copy of the required NDA to you, we can send you the full documentation as soon as we get that back" (you have to wonder what it is in the docs that they're so petrified about getting out that they'd take such measures. Those are a turnoff even to many business customers too - if they're small, they don't have inhouse lawyers to review it and will be uncomfortable about signing it's ), "... is only available as a bare die" (ie, those black epoxy blobs you see on cheap electronics instead of normal chips; that's a die sitting directly on the substrate, with the bondwires between the die and board, then covered with a splash of black epoxy for protection), "....10gbps....", "Radiation hardened" (aka "radhard" - for outer space and niche uses), "Only $163/each", and so on) - there are lots of reasons a part might not be a good match for hand assembly by individuals.

No country selected, please select your country to see shipping options.

No rates are available for shipping to .

Enter your email address if you'd like to be notified when QFN/DFN Breakouts from 6 to 32 pins, 4-12pcs can be shipped to you:

Thanks! We'll let you know when the seller adds shipping rates for your country.

| Shipping Rate | Tracked | Ships From | First Item | Additional Items |

|---|---|---|---|---|

|

:

|

International orders have been suffering long delays due to COVID-19 - please check your country at https://about.usps.com/newsroom/service-alerts/international/ and make sure that I can ship to you, and that you are okay with any delays. There may be additional information available from your national postal service. Some customers have reported packages being delayed in transit by over a month. We cannot offer any sort of guarantees regarding international shipments at this time; we apologize for the inconvenience, and are looking into shipping internationally through UPS.

Please be sure that the address given to Tindie is accurate, and includes your street name and number - company name is only required if shipping to a commercial address. International orders require a valid phone number.

Domestic packages that go more than 1 week without a tracking update will be presumed lost in the mail and refunded or reshipped as buyer prefers. Any international packages can be delayed in customs without warning for 2 weeks or more. After 1 month without a tracking event (2 months to South and Central America - insane delays in those nations are commonplace), we will reship or refund a missing order (as you prefer). COVID-19 update: Some countries have stopped processing incoming international mail entirely -we will cancel orders to countries which we know are not processing international mail at all. This may also cause longer than usual shipping times - we are not responsible for such delays.

We do not open inquiries through the postal service - experience has shown this to be futile.

We ship all orders via USPS. UPS will be added as an option in the near future, I hope. We do all shipping through Stamps.com, and they offer me UPS, but all addresses are rejected as invalid, and I have emailed support numerous times and have had zero response. So at present, we cannot entertain requests to ship through other carriers.

| Quantity | Price |

|---|---|

| 1 | $3.00 |

| 2+ | $2.00 |

No shipping info available.

Set destination country to see options

Shipping to starts at

Free shipping is available to !

Ships from

This item does not ship to .

More Info

Sign up and we'll send a reminder when the seller returns!

somerville, MA, United States of America

Ships from United States of America.

120 Reviews | 2,333 Orders

$3.95

Free Shipping!

$1.70

Free Shipping!

$13.00

Free Shipping!

$5.00

Free Shipping!

$5.50

Free Shipping!

$37.00

Free Shipping!

$3.00

Free Shipping!

$8.00

Free Shipping!

$7.00

Free Shipping!

$1.00

Free Shipping!

$5.25

Free Shipping!

$3.00

Free Shipping!

By clicking Register, you confirm that you accept our Terms & Conditions

We recognize our top users by making them a Tindarian. Tindarians have access to secret & unreleased features.

We look for the most active & best members of the Tindie community, and invite them to join. There isn't a selection process or form to fill out. The only way to become a Tindarian is by being a nice & active member of the Tindie community!